The 'Parsable Project' was a fascinating and complex undertaking during my internship. The

project's main objective was to monitor the data recorded from BIG factories using IoT devices,

ensuring the proper functioning and accuracy of the data collected. As a Data Analyst intern, I

played a vital role in retrieving and analyzing the IoT data to enable real-time monitoring and

decision-making.

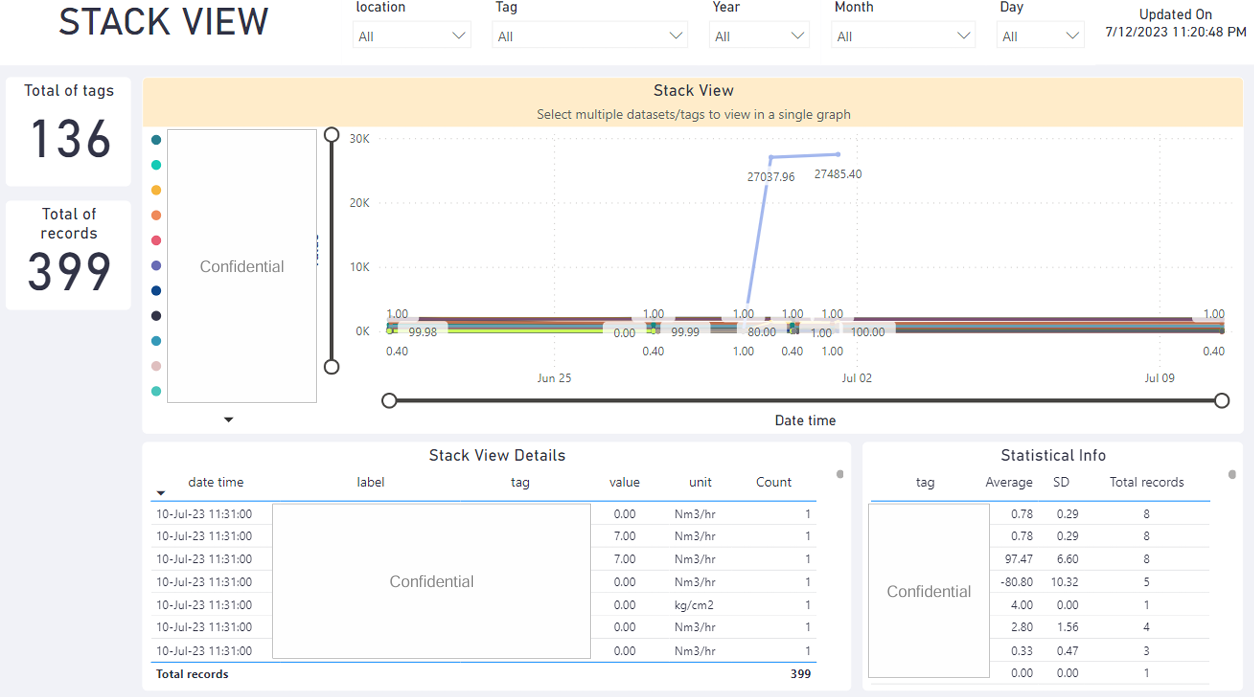

To begin the project, I retrieved the data from the SQL server, following the standard data

retrieval process. Since BIG has numerous factories located throughout Thailand, I recognized

the need for enhanced data accessibility. To achieve this, I incorporated user-friendly filters

in

the dashboard, enabling users to select specific factory locations and datasets they wanted to

monitor.

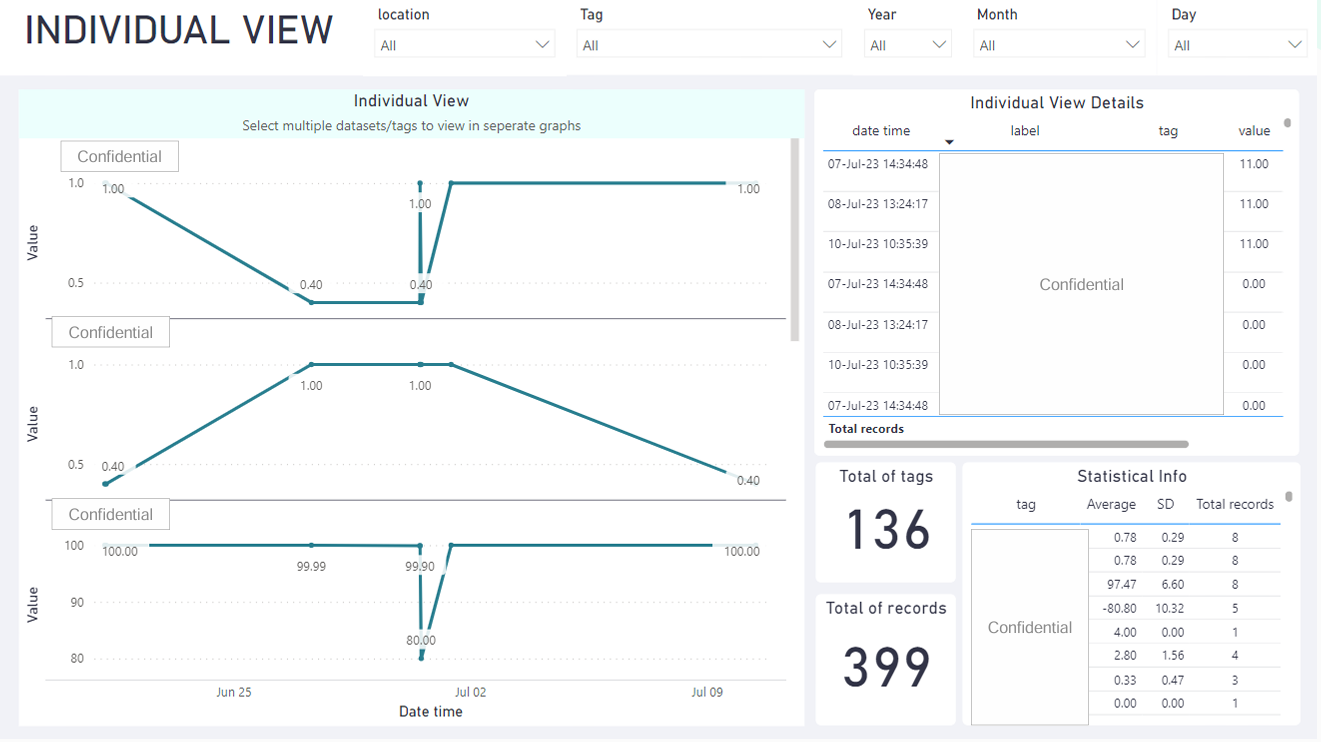

The dashboard's interface allowed users to visualize the IoT data through interactive line

graphs and tables. The line graphs displayed trends and patterns over time, offering insights

into the

performance of various IoT devices and factory processes. The tables provided a detailed

breakdown of the data, facilitating deeper analysis and comparisons between datasets.

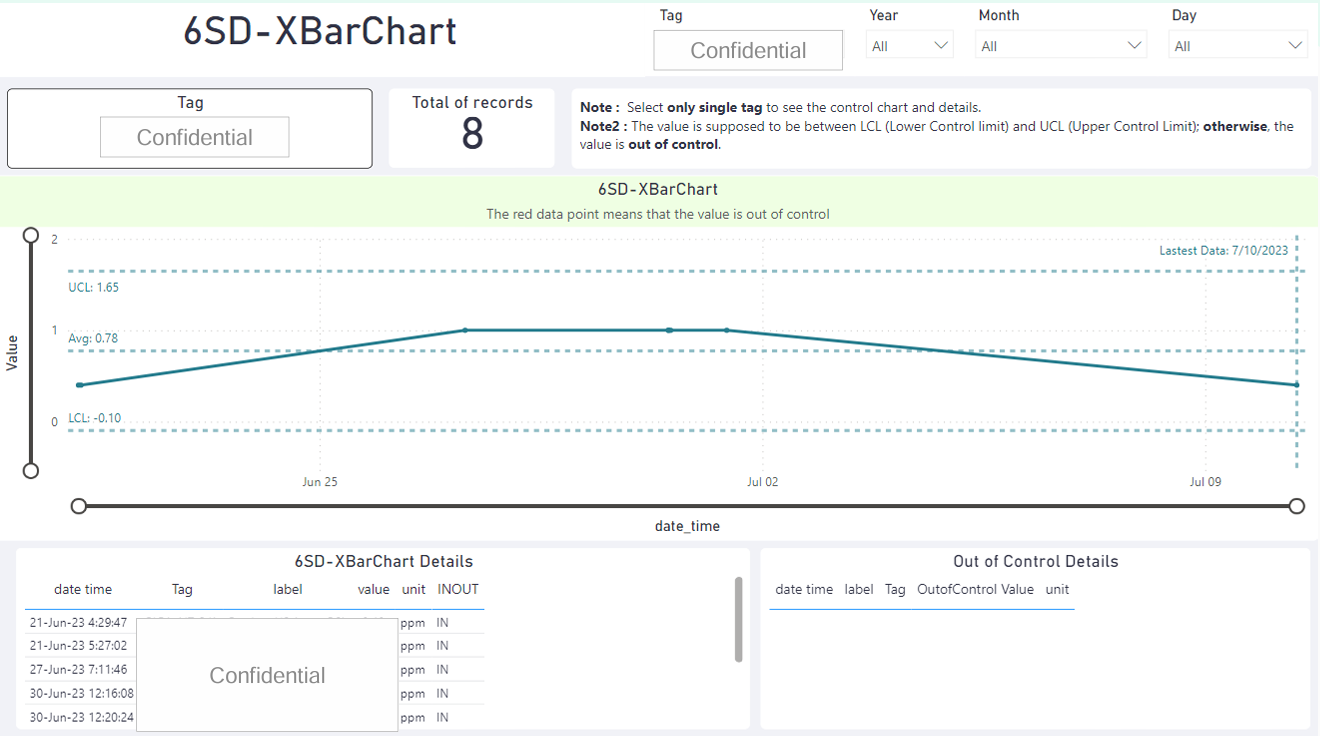

To ensure data quality and identify anomalies, I implemented an X-bar control chart. This

statistical tool allowed users to detect whether the IoT data fell outside the expected range,

indicating potential issues or malfunctions in the factory processes. Additionally, I created a

separate table to store only the out-of-range data for further investigation and swift action.

The 'Parsable Project' posed unique challenges due to the diverse datasets from various factories

and the need for real-time monitoring. The dashboard's design required thoughtful consideration

to

accommodate different user preferences and data visualization requirements. The successful

completion of the 'Parsable Project' not only contributed to the efficient monitoring of BIG

factories but

also demonstrated the significance of IoT data analysis in maintaining optimal production

processes.