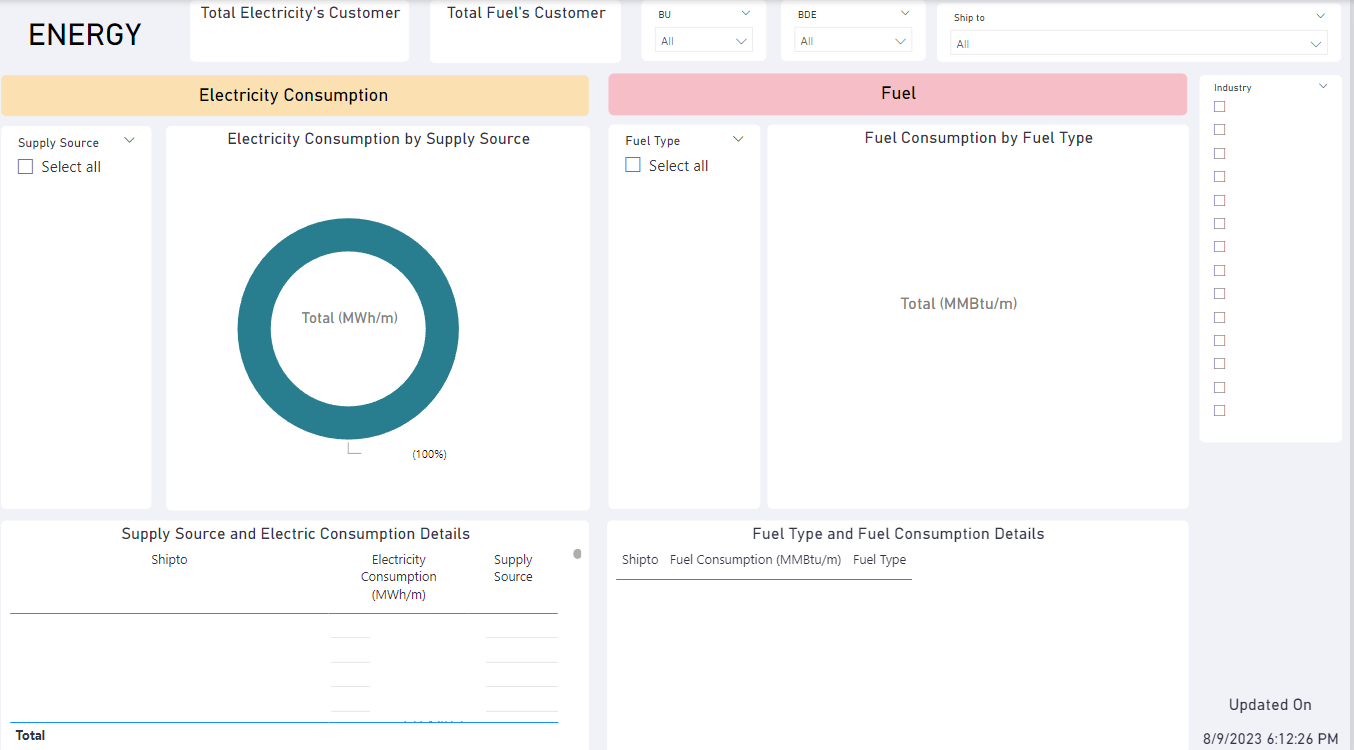

The 'Customer Utility' project was an extensive and challenging endeavor during my

internship. The primary objective of this project was to explore and analyze various

technologies and solutions tailored to different customers' needs. The ultimate goal was to

find suitable solutions for new customers and identify potential customers for existing

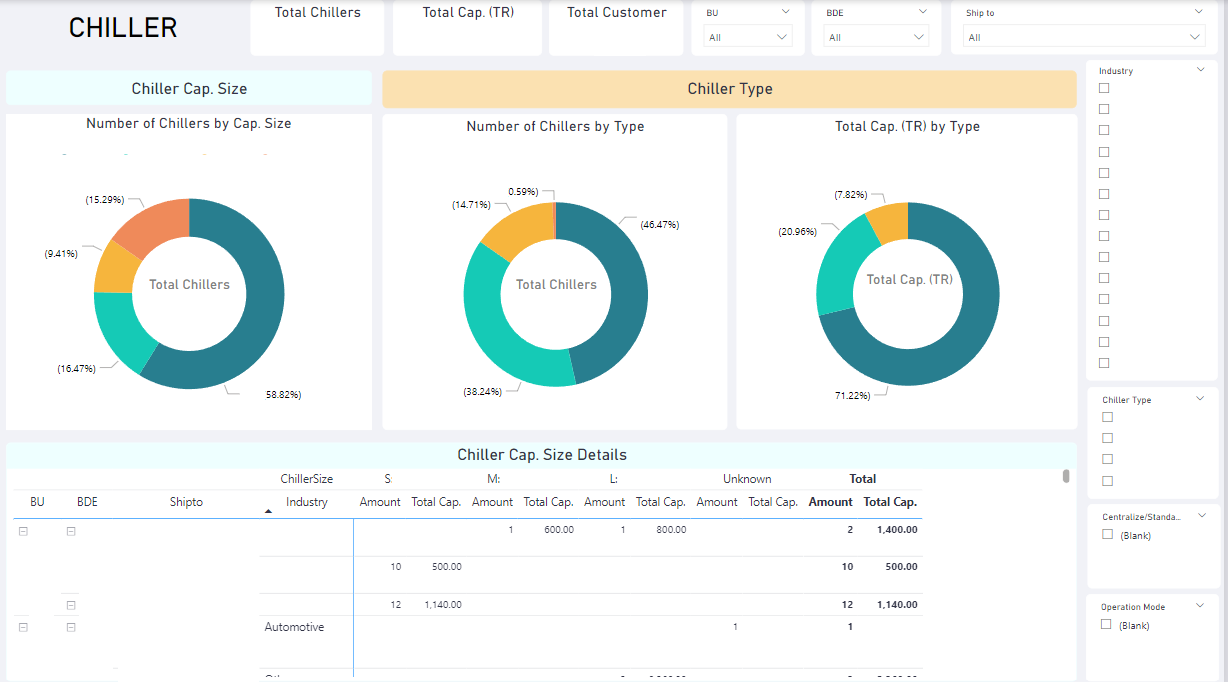

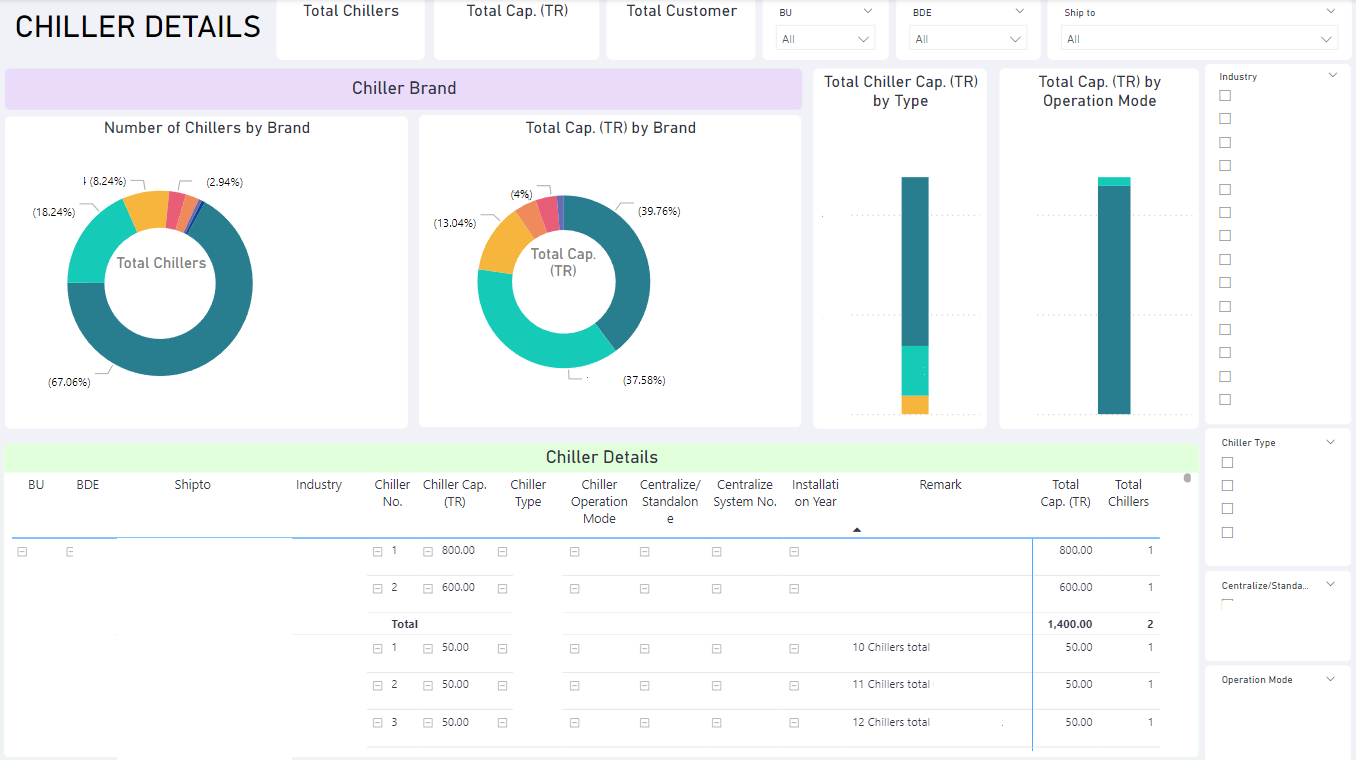

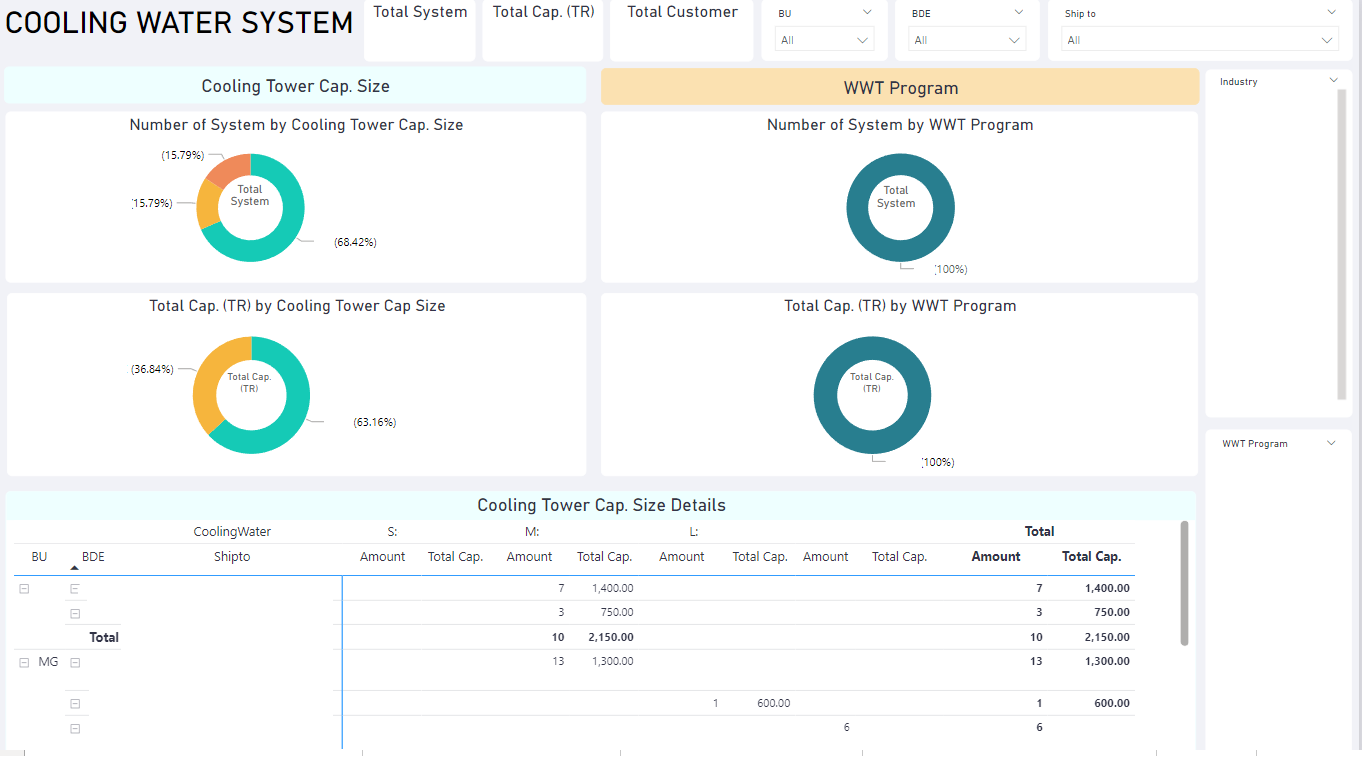

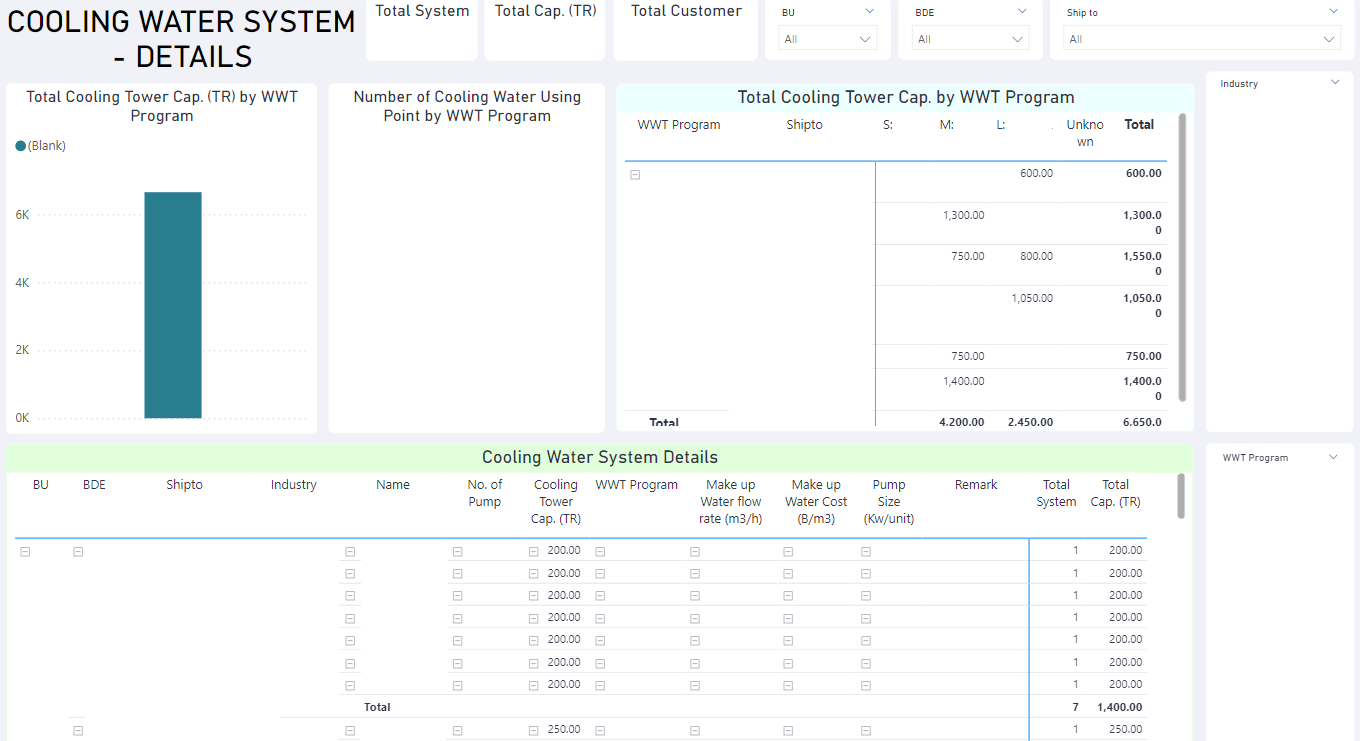

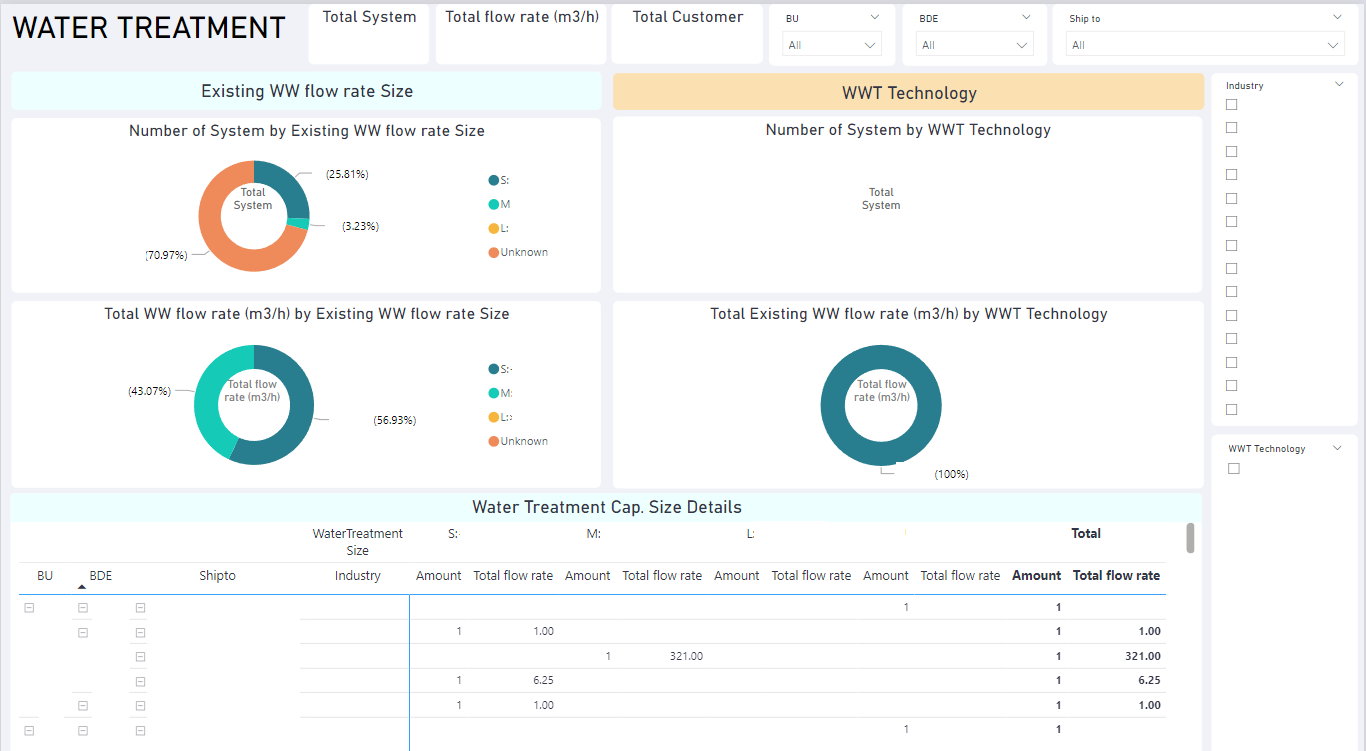

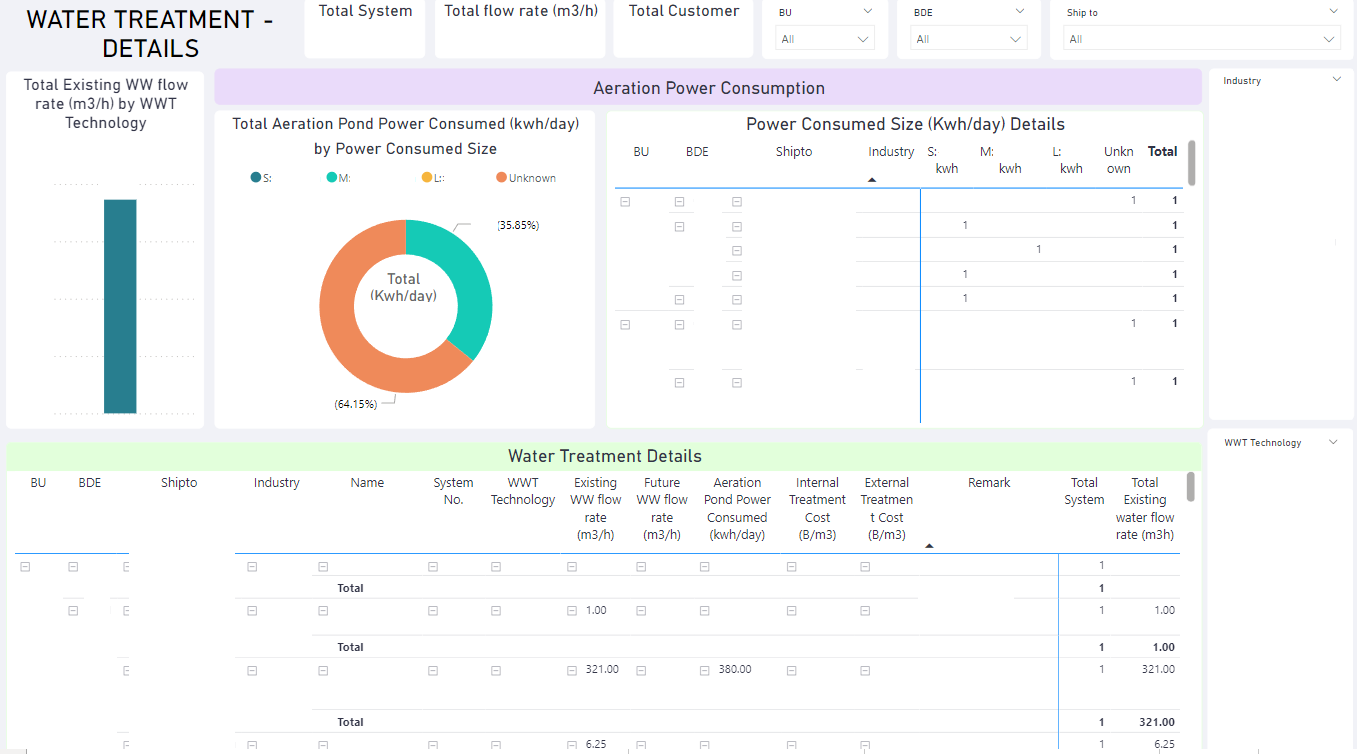

solutions. The project required in-depth analysis of four main technologies: air compressors,

chillers, water treatment systems, and cooling water towers, along with details about power

and fuel consumption

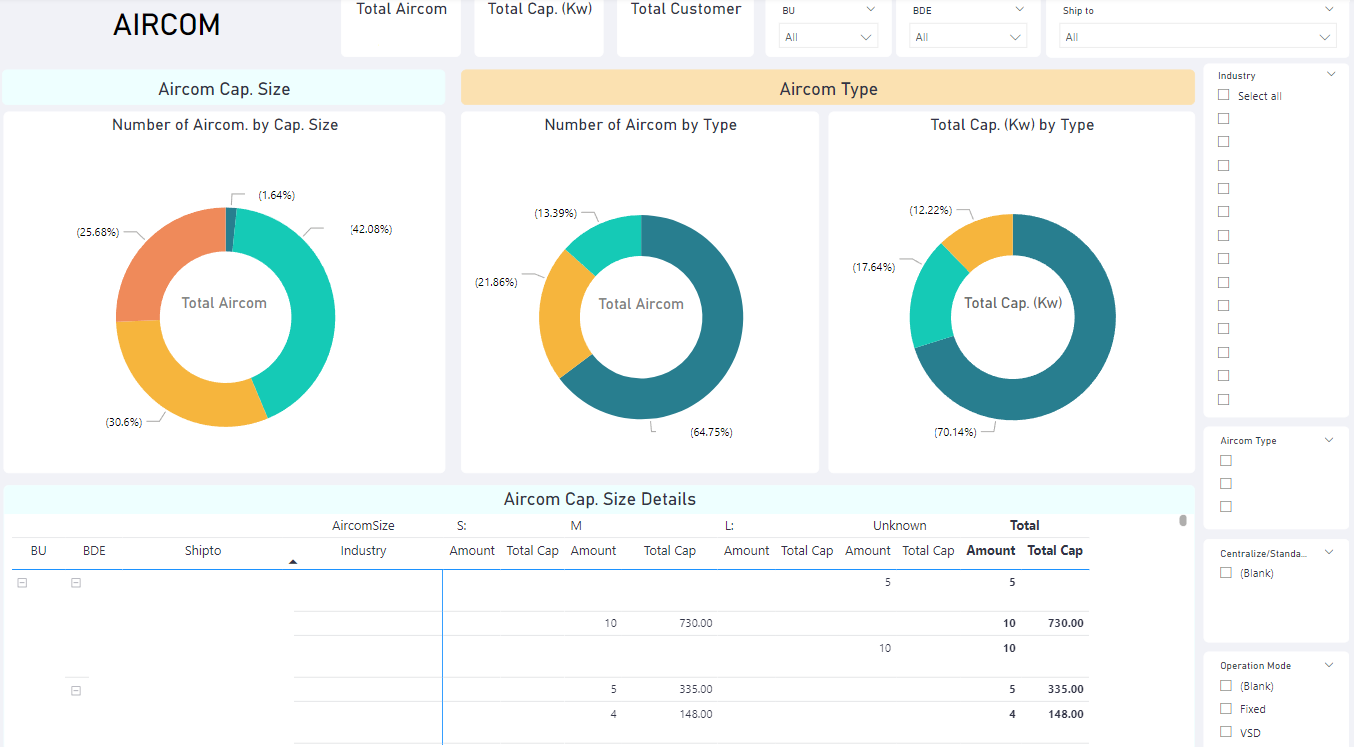

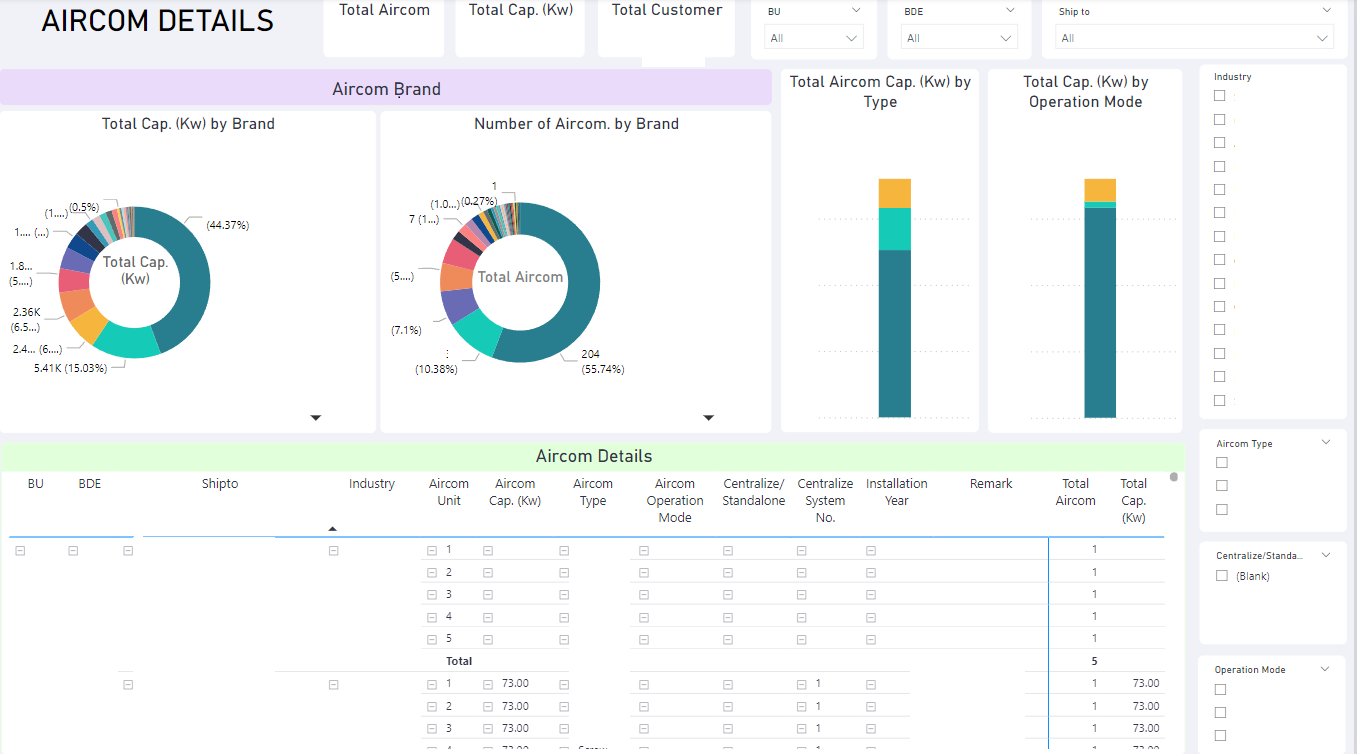

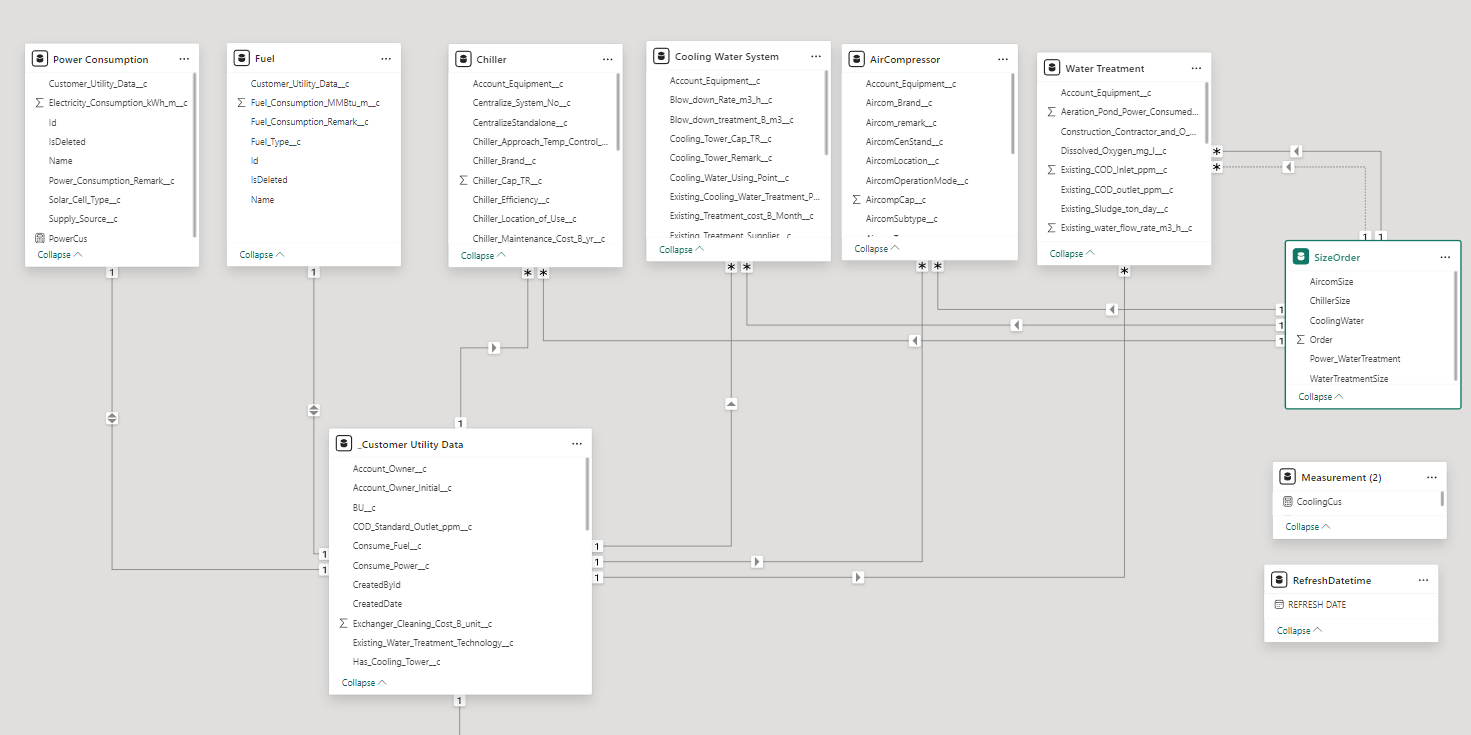

The first step of the project involved matching the appropriate technology to each

customer based on their respective industries. As each technology had specific specifications

and capacities, I had to meticulously match and visualize a vast amount of data. This process

demanded attention to detail and accuracy to ensure the correct technology allocation for

each customer

To facilitate data analysis and decision-making, I further categorized the technology

capacities into small (S), medium (M), and large (L) sizes. Additionally, I conducted various

calculations based on project manager requirements to provide actionable insights and

support strategic planning. Finally, the dashboard consisted of a total of 14 pages, each

dedicated to presenting specific insights and analysis

To ensure data quality and identify anomalies, I implemented an X-bar control chart. This

statistical tool allowed users to detect whether the IoT data fell outside the expected range,

indicating potential issues or malfunctions in the factory processes. Additionally, I created a

separate table to store only the out-of-range data for further investigation and swift action.